|

|

|

| Sprayable

Nanostructured Alumina / Titania S2613P Nanox™ Powder |

| Thermal

Spray Grade Plasma Densified Alumina/Titania is a ceramic composite material used as a wear resistant coating for machine components. Nanox™ S2613P feedstock powder is agglomerated nanoparticles with high density and flowability and an average diameter of 30 µm. |

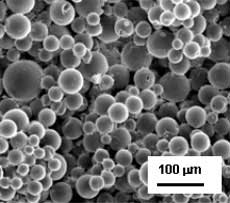

Morphology

SEM micrograph typical of Nanox™ S2613P feedstock powder showing spherical geometry with high flowability. |

| |

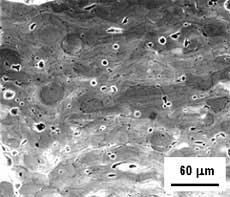

| Coating Microstructure

|

|

||||||||||||

| Properties of NanoxTM S2613P Powder

• 1 nanometer (nm) = 10 -9 meter (m) • Nanoscale Materials for the Global Infrastructure™

|

||||||||||||

| |

||||||||||||

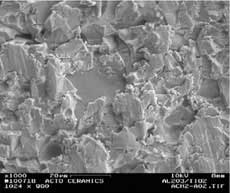

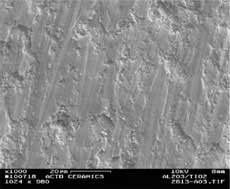

| Wear

Characteristics SEM studies of wear surfaces reveal a morphology difference between coatings sprayed with conventional versus nanostructured alumina/titania. The wear tracks on conventional coatings are rough (grooves, deformation and microfracture), whereas the wear surfaces on nanostructured alumina/titania coatings are relatively smooth (no grooves, deformation or microfracture). Wear resistance is related to toughness, microhardness, and microstructure. Toughness of nanostructured alumina/titania improves the wear resistance of the coatings. Full spray specifications are available through Technical Applications Bulletin No. S2613P.01.A.\ |

||||||||||||

SEM micrograph of worn surface typical of conventional alumina/titania coating. Note: large "plate like" pieces were removed by wear resulting in grain "pull-out."

SEM micrograph of worn surface typical of nanostructured alumina/titania coating made from Nanox™ S2613P feedstock. Smaller pieces were removed resulting in polishing of the coating surface.